Numerous of these waters are used in unique analytical solutions. These nonmonographed waters might not essentially adhere strictly on the said or implied modes of planning or characteristics.

Storage Tanks Storage tanks are A part of water distribution devices to improve processing tools potential. Storage also permits routine routine maintenance within the pretreatment coach while sustaining continuous provide to fulfill production wants. Style and design and Procedure concerns are necessary to prevent or minimize the development of biofilm, to attenuate corrosion, to assist in using chemical sanitization with the tanks, and also to safeguard mechanical integrity. These things to consider may well include things like employing shut tanks with easy interiors, the opportunity to spray the tank headspace using sprayballs on recirculating loop returns, and the use of heated, jacketed/insulated tanks. This minimizes corrosion and biofilm growth and aids in thermal and chemical sanitization.

Packaged waters are made, packaged, and sterilized to take care of their microbiological purity in the course of their shelf life. Alternatively, bulk waters are usually produced on-web-site in which They are really eaten. Just about every type of water has unique purposes, packaging specifications, and top quality characteristics that range according to the pharmaceutical use.

Ordinarily, handful of difficulties are encountered in maintaining the chemical purity of Purified Water and Water for Injection Yet, the arrival of employing conductivity and TOC to define chemical purity has allowed the consumer to more quantitatively evaluate the water's chemical purity and its variability as being a purpose of regimen pretreatment program upkeep and regeneration. Even the presence of these device operations as heat exchangers and use point hoses can compromise the chemical quality of water inside and shipped from an or else very well-controlled water procedure. Therefore, an assessment with the consistency from the water's chemical purity as time passes should be Portion of the validation method. Even so, In spite of one of the most nicely managed chemical good quality, it is frequently more difficult to continuously satisfy set up microbiological good quality standards owing to phenomena transpiring throughout and after chemical purification. A normal program entails intense every day sampling and screening of important process points for at least one month immediately after operational requirements are already founded for each device operation, place of use, and sampling position.

The attributes of conductivity and TOC have a tendency to expose more details on the packaging leachables than they are more info doing with regards to the water's first purity.

Water for hemodialysis. This type of water is specifically for hemodialysis purposes and mainly for the dilution of hemodialysis concentrate solutions.

Calcium, carbon dioxide, and sulfates are all qualitative checks to find out the quantities of these substances inside the water.

By far the most regular aqueous automobile used in pharmaceuticals is water. While in the producing of medicinal items, many types of water are employed, such as.

The dechlorination process might incompletely eliminate the chloramine, which could irreparably destruction downstream device operations, and also the release of ammonia all through this process may well carry by means of pretreatment and stop the completed water from passing compendial conductivity requirements. The purification process have to be reassessed When the consuming water disinfectant is transformed, emphasizing the necessity for a fantastic Doing the job romantic relationship involving the pharmaceutical water manufacturer plus the ingesting water service provider.

At Waterman Engineers Australia, we check here comprehend the value of responsible and higher-good quality storage methods for the pharmaceutical, foods, and cosmetic industries. That’s why we concentrate on the manufacture of AISI 316L stainless steel tanks which can be custom-made to retail store filtered or injectable water stressed or at atmospheric force.

Pure steam is ready from suitably pretreated supply water, analogous to the pretreatment used for purified water or WFI, vaporized with an appropriate mist elimination, and dispersed under pressure.

As with a water system creating purified water, WFI techniques also have to be validated to reliably and continually produce and distribute water of acceptable chemical and microbiological top quality.

. These treatments include uncomplicated sparging from the liquid by having an inert fuel for instance nitrogen or helium followed by inert gas blanketing to avoid oxygen reabsorption. The sparging instances cited range between five to quarter-hour to an unspecified period. Some Purified Water and Water for Injection programs deliver water that may be maintained within a incredibly hot point out and that's inert fuel blanketed during its preparation and storage and distribution.

Our pyrogen-free of charge sterilization systems specifically generate exceptionally secure and trusted units.

Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Danny Pintauro Then & Now!

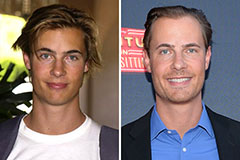

Danny Pintauro Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now!